Here at Wash Water, we can offer you over 100 years of combined water softening experience for commercial and industrial use. We have a very successful relationship with one of the worlds largest softener valve manufacturers (WRAS Approved), supplying equipment tailored to meet your needs. We supply to a wide range of industries and sectors in the UK.

We can supply numerous types of industrial water softeners in either Simplex or Duplex configurations. We design and build our systems to meet the specific requirements of your application and are happy to work with any contractor and specifier to ensure the softener is the right one for their application. Models with ¾” all the way up to 2” connections are available – contact us for more details.

Typical applications are Hotels, Care Homes, Swimming Pools, Restaurants, Car Washes, Caravan Parks, Steam Boilers, Wash Down Areas and where the anticipated usage is not able to be estimated or may well increase during seasonal operations.

For larger units – please contact us.

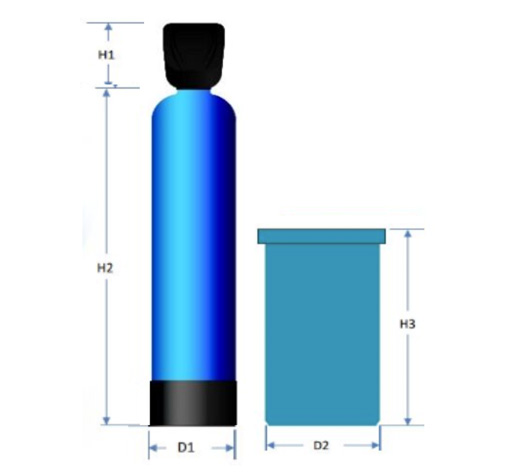

Simplex Softeners

Our Simplex softeners (SM models) have one softening vessel that provides soft water constantly until the softener goes into regeneration but can have an auto shut off solenoid added to the outlet to stop hard water going to service during the regeneration period.

Regeneration on these models is set to 2am, a time when little, if any, water is being used. The regeneration frequency is governed by an integrated water meter, electronic controller and Precision Brining™, which keeps salt use directly linked to the amount of water being used.

This system gives up to 57% salt savings when compared to other simplex softeners available.

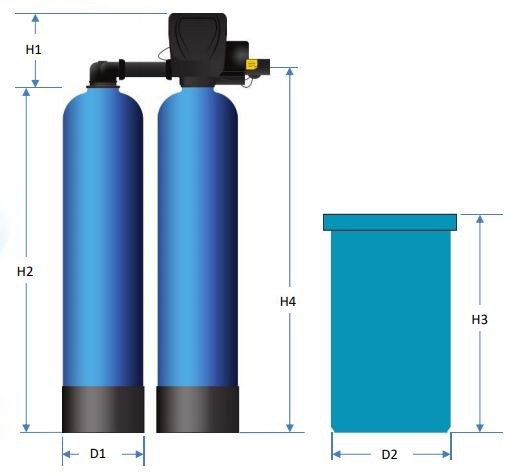

Duplex Softeners

Our Duplex softeners (DS models) are designed to supply softened water in situations where a continuous and uninterrupted supply of softened water is required. These systems have two softening vessels and one brine tank. One vessel provides soft water whilst the other is on standby.

When the supplying vessel becomes exhausted, it automatically switches to a regeneration, with softener water coming from the previous stand by vessel. When the regeneration is finished, it goes onto standby ready to take over from the vessel currently in the supply mode.

There will always be one tank in service while the other tank is running a regeneration cycle or on standby, thereby guaranteeing 24/7 soft water production.